The Problem:

A Western U.S. power company was faced with needing to replace an existing, but obsolete, Turbine Supervisory Instrumentation (TSI). The existing system had all the common turbine monitoring parameters including X/Y Radial Vibration on 10 Bearings, 2 Thrust Position, Speed, Zero Speed/Rate of Acceleration, Eccentricity, HP & LP Case Expansion, Differential expansion, 2 Valve Position and KeyPhasor.

The customer also required "Hard Alarms" with adjustable relays for Radial Vibration, Thrust Position and System OK. Each system channel has independently adjustable relay closures for Alert and Danger, and a separate relay for system OK. This customer wanted relays tied together so there was only 1 terminal block for each parameter; Alert, Danger and System OK. The remaining TSI functions only required Displays so hard alarms/relays were not provided.

Additionally, the customer also had requirements for local display of vibration, speed, valve position and eccentricity. In addition to the local displays, a Digital Modbus TCP/IP communications link to the Plant Data Historian for long term trending of all monitored parameters.

The existing system was mounted in a local instrument panel adjacent to the Turbine Generator Set. The customer wanted to make use of existing sensor wiring and have the system to be a direct “bolt in” replacement utilizing the existing panel openings. Additionally, the customer wanted the system complete to the point they could simply mount panels, provide system power and connect sensors to the intermediate terminal blocks.

To assist with the retrofit, the utility selected Fastrack Technologies LLC, a STI Representative based in Pleasanton. Fastrack Technologies and STI worked together to create a cost effective solution that met all their needs.

The Solution:

Fastrack Technologies principal engineer David Poffenbarger visited the customer's site to develop a workable solution. Fastrack Technologies, working together with STI, engineered a system to minimize impact of removing the old obsolete system, creating a truly “bolt in” solution that could be changed out in only a couple days.

STI manufactured custom "Mimic" and "Monitoring" Panels that directly replaced the old obsolete system, utilizing the existing holes left in the local instrument cabinet. Custom wiring looms were provided to connect the two (2) panels together. Additionally, STI provided CMCP500 Series Monitors and Transmitters, Proximity Probe Systems for Thrust, Vibration, Eccentricity, Keyphasor and Differential Expansion and CMCP-LVDT-AC LVDT's for Case Expansion and Valve Position.

Once the system was manufactured and shipped to the customer, the system was installed during a short unit outage. Fastrack Technologies provided engineering support during the installation and final calibration/setup TSI functions.

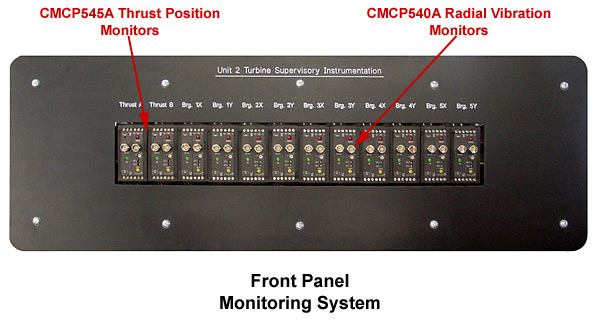

A. Monitoring Panel:

The "Monitoring Panel" included two (2) CMCP545A Thrust Position Monitors and ten (10) CMCP540A Radial Vibration Monitors.

The rear of the "Monitoring Panel" included Redundant +/- 24 VDC Power Supplies, all TSI Function Transmitters and Intermediate Terminal Blocks. Wire guide was provided for a neat and orderly appearance.

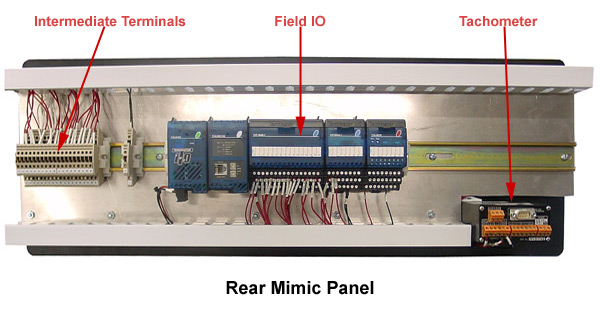

B. Mimic Panel:

The "Mimic Panel" included Bright Red LED Displays of all Thrust, Vibration and TSI Function values, BNC connectors for access to the sensor buffered dynamic output, a machine "Mimic" and a CMCP-Tach3 for Speed, Rate of Acceleration and Zero Speed.

The rear of the "Mimic Panel" included Intermediate Terminal Blocks and Modbus TCP/IP Field IO. IP address was assigned by STI prior to shipment. Wire guide was provided for a neat and orderly appearance.

The entire system is modular and each component can be replaced as needed making maintenance and troubleshooting by customer's personnel straightforward. A complete wiring drawing package was completed for the customer and included in the order.

More info about Fastrack Technologies can be found at www.fastracktechnologies.com or they can they can be contacted at: 925 484-3732 or info@fastracktechnologies.com. David Poffenbarger can be contacted directly at the same phone number or email david@fastracktechnologies.com Mailing address is: PO Box 1821, Pleasanton CA 94566.

If you should have any questions or comments about TSI Systems please contact us. We are here to answer your questions.

|